When it comes to use for natural material floors till date 'Natural Wood' was the only option to consider. But use of Natural wood has been in the form of solid wood planks which was forcing virgin trees to be cut in volumes. Till date Billions of tonnes of Natural wood has been used by Construction conglomerates at the cost of Natural forests. |

D=m/V |

Every rapid interval we hear the news of natural calamities all around the world! |

It is an Epi-centre of the WPC revolution in India. Started way back in 2013 at Ahmedabad in the early phase of WPC Industry, WPC CENTRE has been an application centre, demo centre and education centre for Wood polymer composite technologies and products. It was established for a noble cause of spreading awareness of WPC material within India and globally, to save trees & earth. |

A true product with less calcium contents |

WPC boards can be used for making various applications, apart from modular furniture and doors. This is the best material for quick fixing with cyanoacrylate binder. One can make small articles/gift articles/utility articles very fast with this material. |

| Posted on November 23, 2011 by admin |

Wood-plastic composites (WPC) profiles manufacturers Extruwood GmbH has developed a new PVC-based wood-plastic profiles. This product can be used to replace the wooden window frames on the aluminum edge, especially not solid wood supporting frame. |

| Mr. Hardik Panchal, CEO, Hardy Smith, Ahmedabad |

1. Tell us about yourself. |

2. What is wood polymer composite (WPC), and what makes it so popular nowadays? |

3. What is the utility of WPC in interior and exterior applications? |

4. What peculiarities of WPC make it a suitable material in the making of modular kitchens? |

5. What are the advantages of WPC over natural wood in today’s time? |

6. Can WPC replace other materials like MDF and particle boards, plywood, etc.? |

7. There is a massive growth in the Indian modular kitchen market in recent decades. How do you look at this trend in terms of manufacturing industry? |

8. Do you feel there is an equally big market for WPC in India already for making kitchens? |

9. How can the kitchen designs be made cost-effective in terms of material selection? |

10. What plans do you have to generate awareness about WPC? |

| Posted 1 May 2012 By Anthony Clark | |

| Machinery supplier Cincinnati Milacron is gearing up for an expected growth in the European wood plastic composite (WPC) market of around 20% during 2012. "We are seeing more customers coming to us looking for higher-output machines after realising that their existing plant is just not up to the job," said Steve Jones, Cincinnati Milacron's European business manager and WPC processing specialist. "It's now becoming increasingly apparent that running a basic extruder is just not viable for successful and profitable production of WPCs. "The company is seeing a significant rise in enquiries for replacement screws and barrels for competitive machines due to screw breakage and excessive barrel wear," he added. "It is frightening just how many competitors screws are breaking. As the need for more output increases producers are finding their standard extruders and barrel coating technology are not surviving." |

| Published on August 9, 2011 at 3:05 AM By Cameron Chai |

| companiesandmarkets.com has added a comprehensive report on the global wood-plastic composites market titled, 'Wood-Plastic Composites: Technologies and Global Markets' to its list of offerings. According to the report, the value of wood-plastic composites market including cellulosic plastics and natural fiber composites reached 2.4 Mt in 2011 and it will reach 4.6 Mt in 2016 when it grows at a rate of 13.8% per year. The report not only covers all cellulosic-plastic combinations with each other but with other plastic materials that could be utilized as a replacement for wood materials in the building and construction industry. The report analyzes the plastic-wood composite marketplace in detail with both historic and forecast information for a period between 2008 and 2016. The report includes the profiles of major companies in the market. It also discusses the technologies, strategies, manufacturing processes, product testing, distribution, additive utilization, production costs, pricing and regulations of the industry. Geographic segments of the report include Asia, Europe and North America. The report predicts that automotive and building product segments will be the fastest growing end use segments. The automotive wood-plastic composites market is evidencing a vast growth and would reach a value of 0.8 Mt by 2016 at a compound annual growth rate (CAGR) of 17.1%. The building products market attained a value of 1.78 Mt in 2011 and would attain a value of 3.2 Mt in 2016 at a CAGR of 12.4%. |

| Digital printing on PVC WPC boards is just a unique – easiest process for high resolution printing over any substrate. PVC sheet doesn't need any pre-treatment of surface while printing. You can just print it like a paper. Inkjet flatbed printers available in the market performs well for this value addition and prints really classic quality. Be it a human image or a natural art piece, a modern art or an old memorable family image, a painter's master piece or a children's interest – you can print everything on this surface perfectly. MDF or Wood needs surface finishing and treatment, which PVC sheet doesn't need. You can use Digiprint PVC foam sheets for Doors, wardrobe shutters, kitchen shutters, bookshelf shutters, wall decoration, office places and lot more. Further, applying a coat of PU or melamine for high gloss or mat finish can make your shutter or door a high quality and long lasting product for several years. Digital printing on PVC foam sheet gives several smart creations for architects. You can imagine your ceiling with an image of birds flying in sky or dense garden with flowers or sky shining with stars and moon…just with digital printed PVC sheets. Try it! |

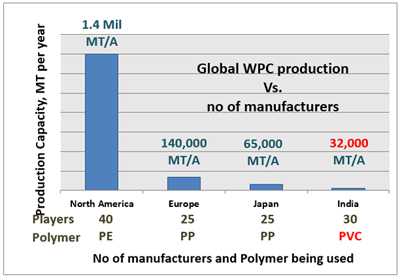

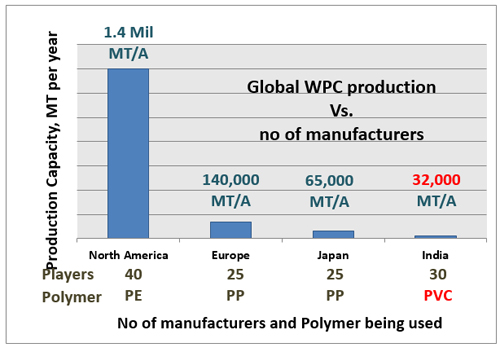

| PLY REPORTER – September 2014, India. Q. Evolution of WPC in India? A. WPC as a product has evolved passionately within last 3 Years. WPC as a panel product is very well accepted by Indian market. Wpc is an official product segment today and there are good manufacturers in the country now. Q. No. of plants (installed and coming) in India, and market size. A. There are 35 WPC board lines and14 WPC profile lines, which is merely 2% of the total wood panel manufacturing of India. Q. How do you see the future of this product in India? Pls give the reasons. A. Very strong of course! This is a product as an investment, not an expense. India is a market where wood panels are in demand today and going to be in demand, untill we reach to a level of other developed countries of the world. Thus in panel category WPC panels would play as a major product in future. We have moisture conditions all around the nation, as country is carrying longer sea coast. Apart from that the land types here supports termite development and spread rapidly and at any height. WPC has moisture resistance and termite resistance, thus the product is being spread pan nation, much positively. The most important reason is its environment friendliness that no fresh trees are cut or used. All we use are sawmill dust or agricultural wastes. Today, India has become a centre for WPC manufacturing with almost 50 lines and lot of foreign inquiries are being received by Indian companies. Q. Why should a dealer sell this product? If he is a dealer for wood panels and allied products than he has ready market for WPC products now. Good quality WPC products have really better margins today. In compare to regular marine or other plywood or MDF panels WPC are becoming popular and real earning products. There are best opportunities available for dealers to be associated with WPC producers. Q. Application area and advantages of WPC. WPC can be used in all modular furniture products e.g. Doors, kitchen carcass, wardrobe shutters, bathroom vanities, partitions and more. For applications like modular kitchen carcass and wardrobe carcass WPC is the best substrate which can be used without any laminate or coating. Refined surface of WPC gives ready to print/paint surface which doesn't need surfacer/putty filling. It can be used with solvent joining which is the fastest ever system for furniture making and sandwich construction. Q. There is lack of awareness in India as well as no govt authorized certification. What is your opinion? Awareness is quite there now and manufacturers have started enjoying supply crisis because of consistently increasing demand. Still I strongly insist for professional marketing, advertising and branding practices from WPC players. There should be carpenter training programs by companies, educating them about product advantages and fast assemblies. I urge for an establishment of WPC manufacturer's association of India, supported by leaders like Reliance, LG or Finolex. As PVC has got a drastic raise in sales volume in the country and have reached to an installed consumption capacity of 50, 000 Metric tones per annum. To support WPC sector for generating larger revenue out of domestic as well as foreign markets, there should be IS standard for these products. There should be a listing under Green category, as product doesn't use any natural/forest wood, doesn't generate process waste, it's 100% recyclable, uses sawmill/agro wastes and saves paper. Q. Presently, who is driving this product in India? and what is your suggestion to specifiers and users? Overall all the players are driving WPC potentially and I would term it as a cooperative effort! Explore numerous applications and educate the market more and more. I will say, USE WPC. Save trees. Save earth. Hardik Panchal HARDY SMITH |

| Plastics extrusion is high-volume longitudinal product manufacturing process in which raw plastic is melted and formed into a continuous profile extrusion produces items such as pipe/tubing, weather stripping, fencing, deck railing, window frames, plastic films and sheeting, thermoplastic coatings and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The materials is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a pipe/profile/sheet that hardens during cooling at lower temperature. At final end, longitudinal shapes are trimmed and cut-to-length as per requirement. T Die technology is a sheet manufacturing device where molten plastic is taking shape as per the internal design and lips fixed on the mouth. T Die on the back is fixed on the extruder head. Sometimes it is fixed with the distributor device where co-extruder are attached for multi-layer sheet manufacturing. T Die is heated with external heaters for supporting the flow of plastic melt inside. T Die is prolonged with calibration molds to form a sheet with certain thickness. Cooling and curing of melt takes place into calibration molds. Lips fixed on the Die held decides about the thickness range of the plastic sheet. |

|

WOOD PLASTIC COMPOSITES |

|

| Almost 300 participants from 21 different countries attended last year’s “Fourth German Wood Plastic Composite” Congress, held on 13 and 14 December 2011 in Cologne / Germany. The mood among them was upbeat, according to organiser nova-Institut (Hürth / Germany; www.nova-institut.de) – a fact that is not surprising considering that the European WPC market has been growing at an average rate of 35% per year since 2005. What’s more, the industry does not expect this impressive track record to slow in the future, banking on ongoing two-figure growth. All in all, about 220,000 t/y of WPC were produced in Europe in 2010, about 100,000 t/y of which were manufactured in Germany alone. Most of this output also went towards the European market, with about 50,000 t assigned to the automotive sector, where WPC is mostly used in compression moulding, while another 167,000 t – the vast majority – was earmarked for terrace flooring, fencing and cladding. According to nova-Institut, in Germany alone, WPC decking commands a market share of about 15%. WPC also increasingly is used for furniture, office and home utensils as well as smaller technical parts and casings, although this share remains rather small, estimated at less than 5,000 t in 2010. Future growth will in part be driven by the rise in traditional plastics prices, nova Institut predicts, saying that "it is only a matter of a few years before WPC pellets are cheaper than pure plastic pellets". At present, WPC – made up of 20-80% bio-based material – is about 20-30% more expensive than traditional resin. |

|

Future growth driven by US, China |

|

| WOODNEWS Magazine, July, 2013, India. Q1: Why are you promoting wood-polymer composite (WPC) when wood is nowadays so freely imported from professionally managed and certified suppliers abroad? |

|||||||||||||||||||||||||||||||||||||

| A1: Wood plastic composite manufacturing doesn't need logs or timbers, but this subject is a boon for wood wastes including sawmill dust, plywood sanding dust, bagasse dust, Rice husk, Jute husk and other forms of wood wastes. WPC product formation can use such natural fibre wastes ranging from 10% to 70% of formulation. Thus directly it has no relation with forests and bigger formats of wood and timbers. This way we are saving forests at the first sight and utilizing waste materials at a great instance. India is being developed as a prominent manufacturing destination for WPC products, globally. Started reversely from international WPC trends India has picked up WPVC panels, rapidly due to all time favourite and upcoming infrastructure developments within the country. India has 'yet to see' situation for furniture industry. The entire agenda of developing the WPC market is to give a life time and quality product for Indian homes, offices, hotels, hospitals and schools. WPC in general can withstand spontaneously against moisture and termite because of its polymeric structure. Today major population of India- taking from slum area to posh villas- are suffering from termite attacks and moisture problems. Natural wood cannot be afforded by 88% of population today. Recent trend in building material and furniture industries is going quite positive with newer materials. Mindset of today’s generation is open, exhaustive and well oriented towards qualitative, innovative, clean & green and value for money products. WPC fits best to their requirements. |

|||||||||||||||||||||||||||||||||||||

| Q2: How does WPC really compare with natural wood in terms of strength, durability, workability and sustainability? | |||||||||||||||||||||||||||||||||||||

| A2: Please find the following properties of WPC boards made with PVC as the core polymer. WPC boards are ideal for panel applications in modular furniture. They can withhold screw well. It has dimensional stability. Moisture and termite resistance gives long lasting durability. Surface is printable. You can apply HPL, Veneer and PVC foils. You can perform carpentry jobs just as like as the natural wood and wood panel. It has good machinability on any panel processing machine. Its polymeric structure with PVC makes WPC 100% recyclable and green material. WPC for India-in indoor applications-is the best material than any other wood panel.

|

|||||||||||||||||||||||||||||||||||||

| Properties of comparison | WPC - Smart wood | Plantation timbers like eucalyptus/ poplar |

| Sturdier core |  |

|

| Recyclable material |  |

|

| Stronger impact resistance | ||

| Low water absorption |  |

|

| Mould resistance |  |

|

| Stain resistance |  |

|

| Rot and splinter free |  |

|

| Easy to cut, router and fasten | ||

| Easier installation |  |

|

| High insulation properties |  |

|

| Aesthetic value | ||

| Ready to use |  |

|

| Termite and borer resistance |  |

|

| Easier to clean |  |

|

| Easier lamination | ||

| Good printing |  |

| Q3: Doesn’t the polymer content in WPC make it less “green” than natural wood? | |

| A3: Green means the product that ‘saves nature – saves natural resources – reduces carbon foot prints – keeps environment clean – uses recycle – can be recycled – has no emission – has no process discharge’. 1. WPC saves trees by not using natural wood from forests – thus it is green. 2. WPC uses the waste wood, wood dust, plywood sanding dust, agriculture waste, and plastic waste – thus it is green as it recycles the natural resources. 3. WPC finished material itself is 100% recyclable and can be reused within the process. WPC products can be recycled anytime during its life cycle – thus is it green. 4. WPC doesn’t emit any gases as a finished product and it is E0 product – thus it is green. 5. Processing of WPC doesn’t create any process waste, waste water or chemical waste – thus it is green. 6. Natural wood, once it is caught up by termite cannot be used again in normal cases. WPC is free from borer and termite – Thus it is green. 7. WPVC like material which is self extinguishing in nature, safe, clean and hygienic-medical grade product – can give a safe and clean life to small children in schools to the employees working in close room conditions. Thus it is green. All above parameters make WPC more “green” than natural wood. |

|

| Q4: How reliable is the formulation of WPC, given that polymers and wood and organic waste do not easily blend or adhere together? | |

| A4: WPC is the better material which can use more agriculture waste with polymers. Conventional wood panels cannot use more agriculture waste those have less fibre value and thus bagasse has been the only successful but saturated option today for particle board and MDF board making. Against WPC can use rice husk, wheat straw, just straw, bagasse, coconut powder, bamboo powder etc with more or equal ratio with polymers. For any polymer formulations there are additives and fillers required and being used globally. Such fillers and additives are used for property enhancement, property achievement and cost reduction purposes. Polymer is a subject where many new experiments can be carried out with use of such additives. Various properties like density, fire retardancy, UV resistance, colouring, bending, heat stability etc can be adjusted with such additives. Finally fillers including mineral and natural fibre can be used effectively within the cell structure to form a WPC polymer chain. |

|

| Q5: What happens when WPC products are rendered useless (breakage, damage in fire, etc.)? Can WPC be recycled? Or will it add to the plastic burden the Earth is already bearing? | |

| A5: WPC is a 100% recyclable product. WPC has a dedicated approach towards wood and allied product replacement, thus it is being used in interior or exterior applications. Country like India has derived WPC as more into interior applications than exterior as of now. WPC is not the commodity plastic but this is a speciality composite known as ‘natural fibre polymer composite’, globally. It has the best uses in furniture industry taking from partitions to modular kitchens. Life of WPC as a product is - far far better than conventional MDF boards, particle boards and plywood – when it comes to moisture, termite and high water conditions in India. Next to its life, WPC can be recycled any time during its life period thus it saves the mother earth from ‘tension of de-forestation’ as well as ‘pressure of re-forestation’. | |

| Q6: How well has WPC caught on globally and in India, in terms of production and business turnover? | |

| WPC has got very well acceptance in recent years in India especially in western, northern and southern parts of India. As a reverse phenomenon WPC is derived more as a panel product – for interiors – with PVC as base material. World market has got more WPC for decking in exterior applications. This phenomenon has taken place naturally because of upraising activities in infrastructure and increasing demands of panel products for partitions, furniture, doors and windows. Within a time span of 2 years, India has become a hub for WPC boards– next to china and becoming equal to china - globally. More than 30 odd players have installed WPC board lines with manufacturing capacity of 10 cubic meters per day, each. In compare to the size of Indian market it equals to the moderate capacity ‘3’ particle or MDF board line of 100 cubic meters per day. This is a massive acceptance of product and today India started receiving export inquiries from developed countries like USA, Europe, Middle East, Africa, and Australia. |

|

|

|

| Q7: Why does India stand out in acceptance of WPC? Is it because of greater awareness of choice? Or is it a case of lower pricing? | |

| A7: As mentioned above, acceptance of WPC is at par to the developed countries. Many new players are being added as manufacturer, dealer, distributor, furniture OEM. In terms of awareness WPC still needs more volume of production. Still product is not reached to each and every corner of India. Architects and interior designers are still not much aware with the product and its decency. Carpenters are still unknown to the product otherwise this is the best product to work with. Many players have started their demonstration centres and exclusive dealers. Education conferences and seminars are also initiated by players like Alstone and Ocean. Better event and media participations are also coming up by many players now. WPC is a classic product when it comes to the case of pricing. It stands moderately with marine ply directly. It stands perfectly with MDF with HPL and even PB with HPL. UV coated WPVC leaves PU coated panels far behind in prices. Printed and Hot transfer laminated WPC boards are about to be launched soon which shall replace ‘Panel with HPL’ application at a high level in wardrobes, kitchens, offices, doors and other panel furniture. |

|

| Q8: Apart from consultancy, you also manufacture WPC-based products. With reference to doors and windows, what has been the turnover year-on-year, over the past 5 years? | |

| A8: We are a technology player and we are not into finished product business. We provide plant, machinery, formulations, installation and manpower for WPC Industry in India and globally. We are establishing a workshop for machine assembling and spares. We are coming up with specialty raw material making facility for WPC industry, soon. We are also planning for operator’s training school at Ahmedabad to supply quality manpower to the industry. WPC industry, as I said has evolved within less than 2 years only so it is hard to provide any record for 5 years with reference to doors and windows. But against UPVC windows industry in last 10 years, WPVC industry’s turnover has reached to around 80 Million USD (500 crore INR) including WPC boards, profiles and WPC decking. | |

| Q9: Who are your biggest (retail, corporate) clients? What/where does the big potential in India lie? | |

| A9: All our clients are from wood and furniture background, except 2 clients from Plastic industry. During last two years we have installed lines for Duraplast (board line), Plamadera composites (board line & flooring line), Lirco composites (board line), Ecoste (board line), Pratham WPC (board line under installation) and I-green fibrex (board line). We are in talks with several corporate clients as of now. In terms of rank in South India comes first considering the weather situation. Next to that Western part has enough potential followed by northern India. East India has equal potential like south because of its developmental scope. |

PLY REPORTER Magazine, January 2016, India. |

Researchers at VTT Technical Research Centre of Finland have developed a kitchen furniture framework material from plastic polymers reinforced with natural fibre. |

RESINS FOR WPC |

WPC sheets can be used for architectural sculptures and murals. Previously we understood about the application of sheets for heritage design preservations. Moving further towards sculptures and murals architects can create unique formations from WPC boards because of its precision for CNC cutting. WPC boards carry outstanding properties for use if outdoor weather applications as shown in the picture. |

Published: 15 August, 2011 |

Technology Partner  Battenfeld-cincinnati is a market leader in extrusion technology that develops, designs, manufactures and distributes innovative, high quality extruders and extrusion equipment. As a global player, battenfeld-cincinnati has 5 production sites in Austria, Germany, China and the USA and an extensive worldwide sales and service network. The company is organized in three divisions (Infrastructure, Construction and Packing). The Construction division provides solutions for window, construction and technical profiles, PVC sheet and wood plastic composites. Battenfeld-cincinnati has been serving the WPC industry for more than 15 years and placed more than 250 tailor-made WPC lines worldwide. Hardy Smith, the only dedicated Indian organization into wood plastic composite sector provides turnkey project solutions including technology, manpower, infrastructure and brand. As a technology player, we are built up by polymer technocrats having hands on experience in wood and polymer sectors. In association with BC extrusion we supports Indian industry for different raw material solutions for making WPC products. Battenfeld-cincinnati Austria GmbH Laxenburger Str.246, 1230 Vienna, Austria Contact : Matthias Daniel (Director Technology-Construction Division) Tel : +43(1)61006-467 Fax : +43(1)61006-55467 Email : Daniel.M@battenfeld-cincinnati.com Website : www.battenfeld-cincinnati.com

Hardy Smith

G-1, Vikram Plaza, below HDFC bank, Gota, Ahmedabad – 382481, India, Contact : Hardik Panchal Tel : +91(79)6545 2427, Mo.: +91-98790 894944 Email : info@hardysmith.org Website : www.hardysmith.org |

The research has great relevance given that disposal of plastic waste by way of landfills induces environmental and space problems while incineration leads to air pollution and aggravation of global warming |

Source – Plastemart.com |

| - Building and construction - Garden and outdoor products - Interiors and internal finishes - Industrial and infrastructure - Automotive - Other low-volume, niche applications |

As per a report by Freedonia, demand for wood-plastic composite and plastic lumber is projected to advance about 10% pa through 2011 to US$5.4 bln. These alternative lumber materials are expected to continue to penetrate the building materials market at a rapid pace, particularly in decking applications. Composite and plastic lumber will continue to benefit from their performance characteristics, such as durability, weatherability, low maintenance requirements and low life cycle cost. Demand for composite and plastic lumber will also be driven by increasing consumer and contractor familiarity, a widening distribution network and product improvements that enhance appearance. Furthermore, ongoing interest in “green” building products will bolster use of composite and plastic lumber made with recycled content. Plastic lumber has found significant use in agricultural fencing, molding and trim applications. Solid growth in decking, fencing and other end uses such as site and leisure furniture will continue to support demand going forward. However, WPC lumber will see much faster growth through 2011, posting gains of 14.3% pa to reach US$2.6 bln. Composite lumber demand will be fueled by strong demand in decking applications. In addition, rapid growth in windows and door applications, as well as smaller niche end uses (porches, site and leisure furniture) will support demand going forward. Among the major product categories window and door applications for WPCs are anticipated to post the most rapid gains through 2011 (albeit from a small base). As with other applications, WPC window and door components are making inroads because of their lower maintenance requirements, durability in exterior applications and similarities to wood. Decking applications are projected to see strong gains through 2011, continuing to increase its relative share of the composite and plastic lumber industry. By 2011, decking will be the largest end use for these alternative building materials, accounting for 44% of demand. Molding and trim will remain a key market for composite and plastic lumber, but will exhibit below-average growth through 2011. Increasing market maturity in the plastic lumber segment will limit growth, as will a weak new housing environment going forward. Fencing applications will see below-average gains through 2011, due to increasing market maturity in the plastic lumber segment. All other applications are projected to see rapid growth over the forecast period from small bases. Playground equipment and site and leisure furniture applications are expected to register strong gains through 2011, driven by the environmentally friendly profile of composite and plastic lumber, as well as their performance and maintenance characteristics. The US wood-plastic composite and plastic lumber industry is highly fragmented, consisting of hundreds of companies ranging from small, regional producers to large, national concerns. Manufacturers typically specialize in one type of material, although some companies offer both composite and plastic lumber. In 2006, the leading composite and plastic lumber firms were Louisiana- Pacific, Royal Group Technologies, Tapco International and Trex. US Wood-Plastic Composite & Plastic Lumber Demand (US$3.4 bln, 2006) |

David Vink, European Plastics News |

Lakda Udyog Darshan, October 2011, India. 'WPC boards' – a fastest running product for Indian, Arab and African Infrastructure markets - By Hardik Panchal, Hardy Smith, India (info@hardysmith.org) Changing product trend as per the cyclic process of product life cycle, WPC boards are replacing shuttering ply boards with its enduring and highly competitive properties. WPC stands for wood plastic composite and this is a unique and evolutionary product derived from a non conventional extrusion process for wood panel industry which has been using pressing technology. As a fortune product for Indian interior and infrastructure industry which is just enjoying its childhood yet in compare to the other developed countries. WPC boards are available with various names like 'Construction boards', 'Crust foam boards', 'Calcium boards', 'WPC shuttering boards' 'WPC MDF boards' in global markets. WPC boards can be produced with flexible density range varies from 400 kg/cum to 900 kg/cum. Another important characteristic is the surface density of this product and which also can be adjusted between a range of 55 shore D to 85 shore D surface hardness. Formulations play a major role in making WPC boards and that is the master key which allows it to be known by different names as above. Wood wastes, Virgin and recycled plastics are key components for making these composite boards. These boards are covering a large application area starting from interior grade boards being used for making furniture, kitchen cabinets, kitchen shutters. Taking further, these boards are being used for making temporary shelters for government housing projects, construction site pavilions/shelters, low cost housing projects and other road and building projects. The high end application of these boards are fall under the category name of 'Construction boards', those are effectively being used as a master replacement of 'Shuttering ply' and 'metal templates'. This board can be used more than 20 times in compare to the conventional shuttering ply used for 4-5 times only. Handling, storage and life are key competitive factors above its all other advantages including moisture repellence, non-deformity in shapes and layers, easy to cut, light in weight. For further information about technology and projects for WPC boards you can write to info@hardysmith.org or visit www.hardysmith.org. |

India's WPC Capacity today |

WPC - Wood Plastic Composite – a promising and sustainable green material

WPC product characteristics WPC does not decay internally, rot or propagate mold. It can be cut, drilled, nailed and sanded like normal wood. All these processing can be done with standard tools. WPC flooring, lumber, cladding can be directly used untreated. WPC production is a 100% safe manufacturing practice having no process waste of materials, as production waste can be easily ground up and processed into top quality product again. This is highly water resistant and resistant to bacteria & insects such as Termite & fungus. Importantly, it can be easily shaped using heat and can be shaped through molds & extrusion technology. Extruded WPC is a highly eco-friendly product & versatile building material to be used for interior and exterior applications. WPC MDF boards can be processed with all panel processing machines like CNC router, Panel saw, Beam saw, Vacuum press, Edge benders, Multi boring and other machines. Absolute moisture resistant property gives biggest advantage of using this product into Modular Kitchen making. A versatile application of Thin MDF for back supports and closures of Modular furniture is very well served with WPC MDF. WPC Doors is fine quality product with uniform polymer structure and can be used for CNC routing for precise and accurate surface engraving. WPC doors cover total application area of one home taking from Main door to bathroom doors. WPC Flooring is a sturdy product and can be used on high water usage areas like swimming pools, gardens, walkways. Same product can be used for bungalows, apartments and offices for exterior and interior surface coverings. WPC planks can be used as a perfect replacement of natural wood for making customized product with carpentry skills. This is a green product and can be made out of wood waste and agriculture waste mixed with Virgin grade and recycled grade thermoplastic materials. |

Lakda Udyog Darshan, July 2013, India.

Courtesy: Plamadera composites, Ahmedabad. WPC decking or WPC lumber against softwood

Courtesy: Libero world, Ahmedabad Q3: How WPC is termed as "Green" in compare to plywood, MDF and timber? A3: Green means the product that 'saves nature – saves natural resources – reduces carbon foot prints – keeps environment clean – uses recycle – can be recycled – has no emission – has no process discharge'. 1. WPC saves trees by not using natural wood from forests – thus it is green. 2. WPC uses the waste wood, wood dust, plywood sanding dust, agriculture waste, and plastic waste – thus it is green as it recycles the natural resources. 3. WPC finished material itself is 100% recyclable and can be reused within the process. WPC products can be recycled anytime during its life cycle – thus is it green. 4. WPC doesn’t emit any gases as a finished product and it is E0 product – thus it is green. 5. Processing of WPC doesn’t create any process waste, waste water or chemical waste – thus it is green. 6. Natural wood, once it is caught up by termite cannot be used again in normal cases. WPC is free from borer and termite – Thus it is green. 7. WPVC like material which is self extinguishing in nature, safe, clean and hygienic-medical grade product – can give a safe and clean life to small children in schools to the employees working in close room conditions. Thus it is green. All above parameters make WPC more "green" than natural wood. Q4: How important is the formulation techniques for WPC where agriculture wastes also are used? A4: WPC is the better material which can use more agriculture waste with polymers. Conventional wood panels cannot use more agriculture waste those have less fibre value and thus bagasse has been the only successful but saturated option today for particle board and MDF board making. Against WPC can use rice husk, wheat straw, just straw, bagasse, coconut powder, bamboo powder etc with more or equal ratio with polymers. For any polymer formulations there are additives and fillers required and being used globally. Such fillers and additives are used for property enhancement, property achievement and cost reduction purposes. Polymer is a subject where many new experiments can be carried out with use of such additives. Various properties like density, fire retardancy, UV resistance, colouring, bending, heat stability etc can be adjusted with such additives. Finally fillers including mineral and natural fibre can be used effectively within the cell structure to form a WPC polymer chain. Q5: Can WPC be recycled or it will add more plastic waste to the earth? A5: WPC is a 100% recyclable product. WPC has a dedicated approach towards wood and allied product replacement, thus it is being used in interior or exterior applications. Country like India has derived WPC as more into interior applications than exterior as of now. WPC is not the commodity plastic but this is a speciality composite known as 'natural fibre polymer composite', globally. It has the best uses in furniture industry taking from partitions to modular kitchens. Life of WPC as a product is - far better than conventional MDF boards, particle boards and plywood – when it comes to moisture, termite and high water conditions in India. Next to its life, WPC can be recycled any time during its life period thus it saves the mother earth from 'tension of de-forestation' as well as 'pressure of re-forestation'. Q6: How WPC is performing in India in compare to Global markets, in terms of product acceptance? A6: WPC has got very well acceptance in recent years in India especially in western, northern and southern parts of India. As a reverse phenomenon WPC is derived more as a panel product – for interiors – with PVC as base material. World market has got more WPC for decking in exterior applications. This phenomenon has taken place naturally because of upraising activities in infrastructure and increasing demands of panel products for partitions, furniture, doors and windows. Within a time span of 2 years, India has become a hub for WPC boards– next to china and becoming equal to china - globally. More than 30 odd players have installed WPC board lines with manufacturing capacity of 10 cubic meters per day, each. In compare to the size of Indian market it equals to the moderate capacity ‘3’ particle or MDF board line of 100 cubic meters per day. This is a massive acceptance of product and today India started receiving export inquiries from developed countries like USA, Europe, Middle East, Africa, and Australia.  Q7: How much successfully WPC is gaining the acceptance in India? What is the status of awareness? A7: As mentioned above, acceptance of WPC is at par to the developed countries. Many new players are being added as manufacturer, dealer, distributor, furniture OEM. In terms of awareness WPC still needs more volume of production. Still product is not reached to each and every corner of India. Architects and interior designers are still not much aware with the product and its decency. Carpenters are still unknown to the product otherwise this is the best product to work with. Many players have started their demonstration centres and exclusive dealers. Education conferences and seminars are also initiated by players like Alstone and Ocean. Better event and media participations are also coming up by many players now. WPC is a classic product when it comes to the case of pricing. It stands moderately with marine ply directly. It stands perfectly with MDF with HPL and even PB with HPL. UV coated WPVC leaves PU coated panels far behind in prices. Printed and Hot transfer laminated WPC boards are about to be launched soon which shall replace ‘Panel with HPL’ application at a high level in wardrobes, kitchens, offices, doors and other panel furniture. Q8: What services Hardy Smith is providing for WPC technology in Indian market? A8: We are a technology player and we are not into finished product business. We provide plant, machinery, formulations, installation and manpower for WPC Industry in India and globally. We are establishing a workshop for machine assembling and spares. We are coming up with specialty raw material making facility for WPC industry, soon. We are also planning for operator’s training school at Ahmedabad to supply quality manpower to the industry. We have a business cooperation with Battenfeld-cincinnati, Austria who the largest global player into WPC industry with 250 lines. WPC industry, as I said has evolved within less than 2 years only so it is hard to provide any record for 5 years with reference to doors and windows. But against UPVC windows industry in last 10 years, WPVC industry’s turnover has reached to around 80 Million USD (500 crore INR) including WPC boards, profiles and WPC decking. Q9: Who are your clients in India? Nationwide, how do you see WPC markets? A9: All our clients are from wood and furniture background, except 2 clients from Plastic industry. During last two years we have installed lines for Duraplast (board line), Plamadera composites (board line & flooring line), Lirco composites (board line), Ecoste (board line), Pratham WPC (board line under installation) and I-green fibrex (board line). We are in talks with several corporate clients as of now. In terms of rank in South India comes first considering the weather situation. Next to that Western part has enough potential followed by northern India. East India has equal potential like south because of its developmental scope. |

WPC – Becoming popular amongst Re-sellers and End users HARDY SMITH, India. |

WPC PVC foam sheets –Replacing Plywood, MDF & Natural wood in furniture applications |

Best practices witnessed in last years for modular kitchen manufacturing is with MDF or Plywood panels because of its engineered structure and dimensions. These panels are in practice to be used with mandatory laminations of HPL/Paint on front and back surfaces. This is not only for decoration but also to protect the wooden material from moisture and termite. For high end applications PU laminations are in practice. But the basic structure of the panel is still wood and cannot be considered 100% water proof or termite proof. WPC BOARDS a new generation panels derived technically from Polyvinyl chloride polymer and natural fibre (saw mill dust or agriculture fibre e.g. rice husk) composite. Globally it is termed as natural fibre polymer composite or wood polymer composite. |

WPC CARCASS – An application becoming ‘mandatory’… |

WPC CNC GRILLS - A modern material for preserving heritage… |

WPC DOORS | WPC SOLID DOOR FRAMES |

|

WPVC board – it was brown actually. Now it is white as well as colorful too! HARDY SMITH, India. Poly vinyl chloride – is an instrumental material behind the making and formulating of wood polymer composites, in case of India. India is becoming popular destination for PVC based WPC. Country is witnessing a continuous growth with addition of new players regularly since last 4 years now. Indian exhibitions are adding stalls for WPC products now for new brands. A lot of activities are going on for this product and its promotion, carpenter meets, and architect meets etc at different levels are on. Product showcasing also is in action and you can find exclusive ‘WPC CENTRE’s in action.

PVC is the subject of formulation and you can customize your product to differentiate your entity. Having best insulation properties WPVC boards can reduce consumption of electricity almost 25%, as it doesn’t permit heating or cooling to pass through. WPVC ceiling panels are available now. WPC due to its fire properties as above catches attention of the government departments and many new projects are being done with WPC doors, door frames and partitions in customized colors. WPVC door frames and Doors can be made in any natural wood shade e.g. Pine yellow, Teak red, Wenge brown and many more. WPC Floors also can be made colorful in solid colors. |

|

WPC MODULAR KITCHEN – A waterproof, termite proof, clean & hygienic set up for homes |

|

VERTICAL GARDEN ON WPC SHEETS |

|

Wood Polymer Composite |