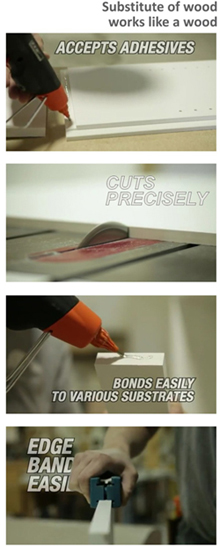

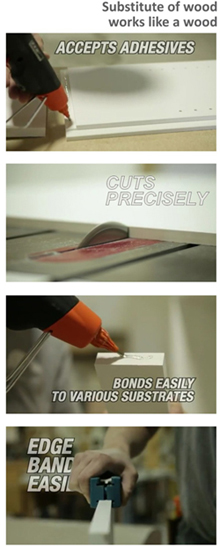

WPC is a revolutionary product for carpenters and carpentry system. The way it makes the furniture assembly - with no screw - solvent joinery system - no other wood panel can do! Few minutes of bonding gives permanent bondage to the component joints.

It is very much easy and smooth to work with WPC panels. Tools' life get increased with less abrasion and friction with structure. Time and energy of carpenter is saved almost 50% working with WPC panels.

This is the time for smart carpentry with quality product. This is the time to use light weight structures. This is the time to use green products. WPC panels are here for these all. You can save energy on your machines with low load working conditions. You can deliver your jobs much faster than before and you can shift to the next assignments. Thus you can increase your turn over.

Now you can install kitchens and cupboards in a day or two. Kitchen carcasses do not need to apply with two side HPL now. It can be erected with just WPC panels, a few screws and PVC solvent cement. Similar with wardrobes and bedrooms. Children furniture can be best made with this material, as it doesn't have sharp edges and delaminated layers.

WPC panels can be painted fast with lesser consumption. Panels can be UV coated and PU coated for high end applications. You can apply HPL, Veneer, Paper, PVC foil. You can make sandwich structures by joining WPC to WPC, WPC to particle board, WPC to MDF board, WPC to Plywood and WPC to wood and OSB too.

You can use WPC panels on any panel processing machine taking from panel saw to edge banding and multiboring to spindle moulder. The highest level you can use it for manual routing and CNC routing.

WPC panels are techno-commercially best fit product for carpenters. You can use the same hand tools and typical carpentry instruments.